Orders ship the second + fourth Mondays/Tuesdays of the month [SEE DATES HERE].

Next shipping dates: Nov. 11, Nov. 18 (SPECIAL DATE), NO Nov. 23 due to the holiday; Dec. 9 (last shipping day of the year) Pick up date: tbd

Orders ship the second + fourth Mondays/Tuesdays of the month [SEE DATES HERE].

Next shipping dates: Nov. 11, Nov. 18 (SPECIAL DATE), NO Nov. 23 due to the holiday; Dec. 9 (last shipping day of the year) Pick up date: tbd

The Journey of our meat: From farm to butcher

As farmers, we are involved in nearly every step of getting meat from our farm to your table. However, when it comes to butchering and packaging, we partner with other small businesses that specialize in this crucial part of the process.

We’re often asked if we cut and package the meat ourselves, so I wanted to share more about how this works. Our farm works with federally inspected meat processors—often referred to as butchers, abattoirs, or meat lockers.

What Does Federal Inspection Mean?

Federal inspection means that a third-party inspector, employed by the U.S. Department of Agriculture (USDA), is onsite during the entire process. Their role is to monitor the safety and quality of the harvest, meat cutting, and packaging conducted by the local butcher.

When you purchase our goat meat, you’ll see a USDA inspection stamp on the label. This stamp verifies that our meat has gone through rigorous inspection. The same applies to the meat you find from other farmers or in grocery stores.

If you purchase meat from other farmers, you might notice a state-inspected stamp instead. This means the process was monitored by state meat inspectors rather than federal ones. While the inspection process is similar, state-inspected meat cannot be sold across state lines.

Why We Use a USDA-Inspected Butcher

We chose to work with a USDA-inspected butcher because we sell our meat outside of Wisconsin. To legally sell meat across state lines, it must be processed at a federally inspected facility.

Even before we started shipping nationwide, our farm was already working with a USDA-inspected butcher due to our proximity—just 30 miles from the Minnesota border. This allowed us to serve families across our local footprint.

The Challenges of Working with Meat Processors

The number of USDA- or state-inspected meat processors available to farmers is limited. This means many farmers must transport their livestock long distances—often an hour or more—to reach a processor.

We’re fortunate that our closest facilities are only 1 to 1.5 hours away, but we know farmers who make four-hour round trips just to drop off and later pick up their processed meat.

Additionally, due to high demand for local and independent meat processing, booking a slot at the butcher requires advance planning. Farmers often wait several months—or even schedule appointments a year ahead.

On our farm, we plan our processing needs a year in advance based on the number of animals we anticipate harvesting. But it’s not just about numbers—it’s also about timing livestock growth to ensure they reach the right size and age. On the retail side, we also consider:

✔️ What cuts are in demand based on seasonality

✔️ General customer preferences

✔️ Ensuring our Farm Club (subscription box) members get the variety they need

The Hard Work Behind the Meat Processing Industry

The work at a meat processing facility is physically demanding. Employees typically start early and handle a variety of tasks—from cutting and packaging meat to retail work.

Many of the butchers we work with operate as small, independent businesses, with a dedicated team that is cross-trained in multiple areas of the operation, including management and ownership.

Stay Tuned for Part Two

In our next newsletter, we’ll take a deeper dive into what happens after we get our meat back from the butcher—covering the retail side of the process and how we prepare it for you.

Also in Leslie's Blog

Cabrito featured on Hardcore Carnivore on the Outdoor Channel

Cabrito takes the spotlight in Hardcore Carnivore’s newest goat-focused episode

An Update on Shipping Rates

We wanted to take a moment to share a change we’ve recently had to make to our shipping rates.

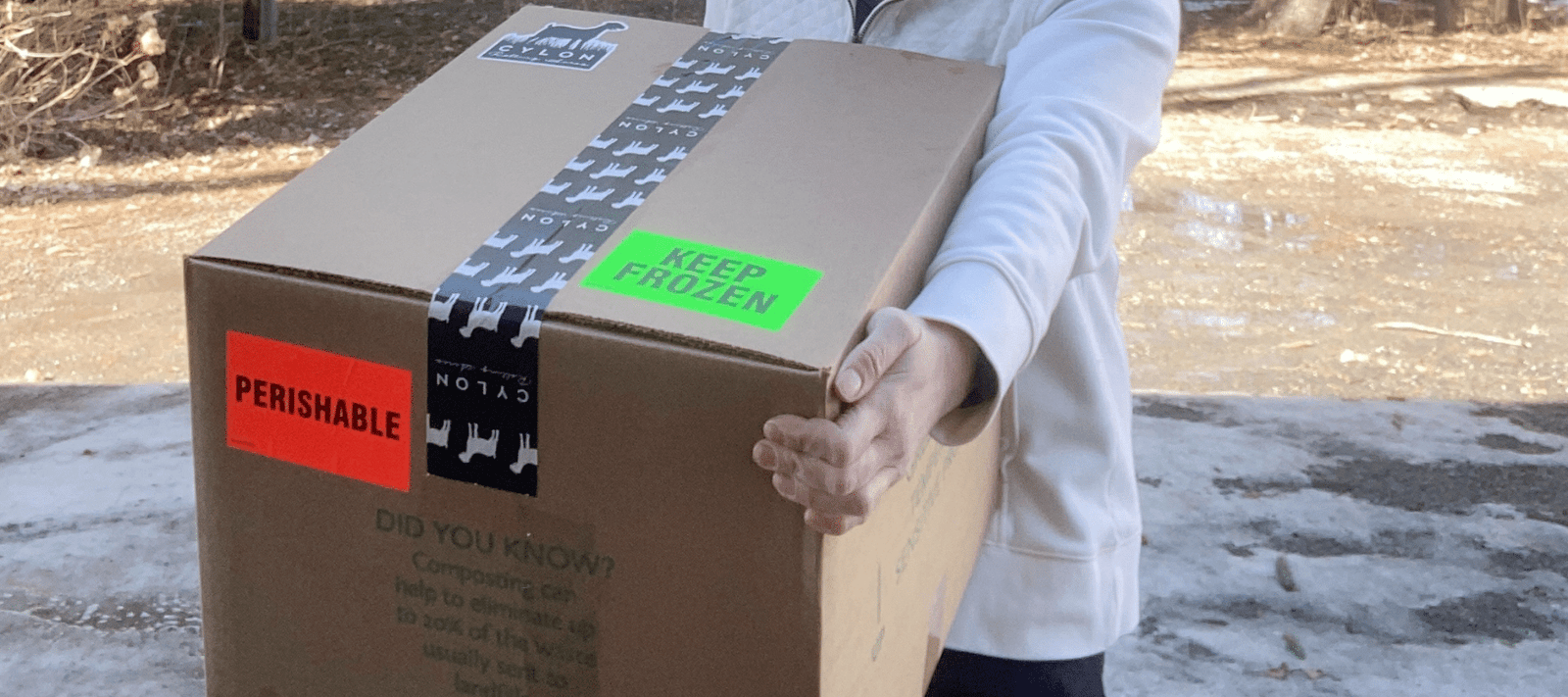

A Day in the Life Packing Orders

Come along with me as I pick up supplies for order day, pack boxes and get them ready for UPS pick up.